Ukuqaliswa kweendlela ezintlanu zeplastiki zeplastiki zokuwelda

Kwiminyaka yakutshanje, ngophuculo oluqhubekayo lwetekhnoloji, i-laser welding yeplastiki iya kubonisa ngokuthe ngcembe umkhwa okhulayo kwixesha elizayo.Kule minyaka imbalwa idlulileyo, obunye ubuchwephesha belaser abukagqobhokanga, kwaye ixabiso lelaser liphezulu kakhulu.Xa kuthelekiswa ne-welding yendabuko, utyalo-mali lwexesha elinye lukhulu, olunokuthi lungavelisi inzuzo ngokukhawuleza.Kodwa ngoku inzuzo yezoqoqosho yelaser ibonakalisiwe.I-laser welding yeplastiki inokunciphisa ubunzima kubayili bokuyila iimveliso.

Okwangoku, iimveliso ezininzi (kubandakanya ishishini le-semiconductor yemoto, ishishini lamayeza kunye nokutya, njl.njl.) zineemfuno eziphezulu kakhulu zokulungiswa kokuchaneka kunye nenkangeleko yobuhle, eyenza i-laser iwelding ibe yinkqubo eyimfuneko yokuveliswa kwezi mveliso kwaye ikhuthaze uphuhliso oluthe kratya. iteknoloji ye-laser welding.

Ukusondela kokuhambelana, ubushushu bokudibanisa kunye nokuhambelana kweplastiki ye-laser welding, ngcono umphumo wayo uya kuba.Imowudi yokusetyenziswa kwelaser yeplastiki yokuwelda yahlukile kuleyo yokuwelda isinyithi, kubandakanywa ukuwelda okujikelezayo okulandelelanayo, i-quasi synchronous welding, i-synchronous welding kunye ne-irradiation mask welding.I-Olay Optoelectronics izakwazisa ngokufutshane ezi ndlela ze-welding.

1. Welding profile

Ilaser ihamba ecaleni komgca wecontour yomaleko wokuwelda iplastiki kwaye iyinyibilikise ukuze ngokuthe ngcembe idibanise iileya zeplastiki kunye;Okanye uhambise isanti kunye ne-fixed laser beam ukufezekisa injongo ye-welding.

Kwizicelo ezisebenzayo, i-contour welding ineemfuno eziphezulu zomgangatho wamalungu abunjiweyo enaliti, ngakumbi ukusetyenziswa kwemigca ye-welding enzima efana nezahluli ze-oyile-gas.Kwinkqubo yeplastiki ye-laser welding, i-contour welding inokufikelela ekungeneni okuthile komgca we-welding, kodwa oku kungena kuncinci kwaye akulawuleki, nto leyo efuna ukuba ukuguqulwa kweendawo zokubunjwa kwenaliti akufanele kube kukhulu kakhulu.

2. I-synchronous welding

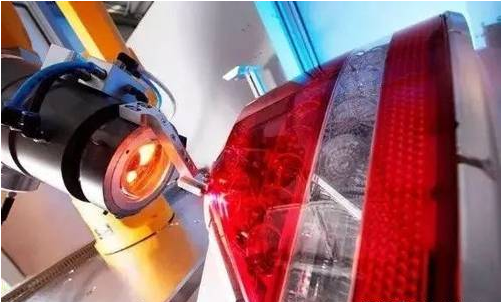

I-laser beam evela kwii-laser diode ezininzi zenziwe ngezinto ezibonakalayo.Umqa we-laser ukhokelwa kumgca wecontour we-welding layer kwaye uvelisa ubushushu kumthungo we-weld, ukuze wonke umgca wecontour unyibilike kwaye udityaniswe kunye ngexesha elinye.

I-synchronous welding isetyenziswa ikakhulu kwizibane zemoto kunye neshishini lezonyango.I-synchronous welding yi-multi-beam, i-optical shape ibonisa indawo ekhanyayo ye-welding track, ebonakaliswe ngokunciphisa uxinzelelo lwangaphakathi.Ngenxa yokuba iimfuno ziphezulu kwaye ixabiso lilonke liphezulu, lisetyenziswa ngokubanzi kunyango lwezonyango.

3. Ukuskena ukuwelda

Umzobo we-laser welding welding

Ukuskena ukuwelda kukwabizwa ngokuba yi-quasi synchronous welding.Itekhnoloji ye-welding yokuskena idibanisa ezi teknoloji zimbini zokuwelda, ezizezi, ulandelelwano lwe-welding ye-welding kunye ne-synchronous welding.Isibonisi sisetyenziselwa ukuvelisa isantya esiphezulu se-laser beam kunye nesantya se-10 m / s, ehamba ecaleni kwendawo ukuze idityaniswe, isenza ukuba yonke inxalenye ye-welding ifudumale kwaye idibanise kunye.

I-Quasi synchronous welding yeyona isetyenziswa kakhulu.Kumashishini amacandelo emoto, isebenzisa i-galvanometer ye-XY ephezulu ngaphakathi.Undoqo wayo kukulawula ukuwa kweplastiki ye-welding yezinto ezimbini.I-Contour welding iya kuvelisa uxinzelelo olukhulu lwangaphakathi, oluya kuchaphazela ukutywinwa kwezinto.Ulungelelwaniso lwe-Quasi yindlela yokuskena ngesantya esiphezulu, kwaye ngokulawulwa kwangoku, inokuphelisa ngempumelelo uxinzelelo lwangaphakathi.

4. I-welding eqengqelekayo

Umzekeliso we-laser rolling welding

Ukuqengqeleka kwewelding yinkqubo yokuwelda iplastiki yelaser, eneendlela ezininzi ezahlukeneyo.Kukho iindidi ezimbini eziphambili ze-rolling welding:

Eyokuqala yiGlobo ball welding.Kukho ibhola yeglasi ye-cushion yomoya ekupheleni kwelensi ye-laser, enokuthi igxininise i-laser kwaye ibambe iindawo zeplastiki.Kwinkqubo ye-welding, i-lens ye-Globo iqhutywe yi-platform ye-motion ukugqiba i-welding ngokuguqa kunye nomgca we-welding.Yonke le nkqubo ilula njengokubhala ngepeni yokubhala.Inkqubo ye-globo welding ayifuni i-complex fixture ephezulu, kodwa kuphela imveliso yenkxaso ye-mold ephantsi.Inkqubo ye-welding yebhola ye-Globo nayo inenkqubo ye-welding ye-roller eyahlukileyo.Umahluko kukuba ibhola yeglasi ekupheleni kwelensi iguqulwa ibe ngumbhobho weglasi wecylindrical ukufumana icandelo elibanzi lelaser.I-roller ye-welding ifanelekile kwi-welding ebanzi.

Okwesibini yinkqubo ye-welding ye-TwinWeld.Le nkqubo yeplastiki ye-laser welding yongeza i-roller yesinyithi ekupheleni kwe-lens.Ngethuba lenkqubo ye-welding, i-roller icinezela umda we-welding welding.Inzuzo yale nkqubo yeplastiki ye-laser welding kukuba ivili lokucinezela isinyithi aliyi kunxitywa, elilungele imveliso enkulu.Nangona kunjalo, uxinzelelo lwe-roller yoxinzelelo lusebenza kumda we-welding line, ekulula ukuvelisa i-torque kunye nokwenza iziphene ezahlukeneyo ze-welding.Kwangaxeshanye, ngenxa yokuba ulwakhiwo lwe-lens lunzima ngokwentelekiso, kunzima ukucwangcisa i-welding.

5. I-Irradiation mask welding

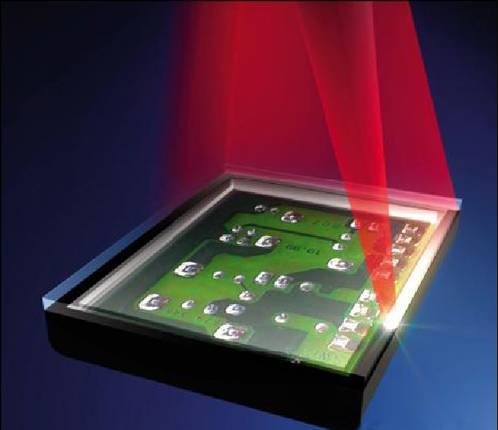

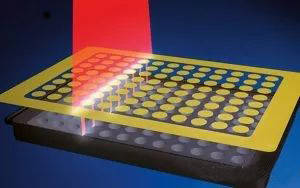

I-Laser irradiation mask welding diagram

I-laser beam ibekwe kwi-template ukuze inyibilike kwaye idibanise iplastiki.Ithemplethi iveza kuphela inxalenye encinci ye-welding echanekileyo kumaleko eplastiki angezantsi.Umqa we-laser utshisa kuphela inxalenye yemveliso engagqunywanga yimaski.Le teknoloji ingasetyenziselwa ukufikelela kwi-welding ephezulu echanekileyo ephantsi njenge-10 microns.

Amacandelo e-microfluidic anokuthi achaneke kwaye agxininiswe ngokuzinzileyo ngumgaqo we-mask welding.Ijiyometri yomjelo iya kuhlala injalo, inqanda ukunyibilika kumjelo omxinwa we-200 µ m.

Ixesha lokuposa: Oct-21-2022