NgoMeyi ka-2022, i-CCTV ibike ukuba idatha yakutshanje evela kuLawulo lwaMandla kaZwelonke ibonisa ukuba ngoku, iiprojekthi zokuvelisa amandla e-photovoltaic ezisakhiwayo ziyi-kilowatts ye-121 yezigidi, kwaye kulindeleke ukuba umbane wonyaka we-photovoltaic uza kufakwa ngokutsha kwigridi. nge-108 lezigidi zeekilowatts, ukwanda ngama-95.9% kunonyaka ophelileyo.

Ukwanda okuqhubekayo kwe-PV yehlabathi jikelele efakwe amandla kuye kwakhawulezisa ukusetyenziswa kweteknoloji yokucubungula i-laser kwishishini le-photovoltaic.Uphuculo oluqhubekayo lwetekhnoloji yokucubungula i-laser kuye kwaphucula ukusetyenziswa kakuhle kwamandla e-photovoltaic.Ngokwezibalo ezifanelekileyo, imakethi yePV entsha efakiweyo ifikelele kwi-130GW ngo-2020, yophula imbali entsha.Ngelixa i-PV yomhlaba wonke efakelweyo umthamo ufikelele kwinqanaba eliphezulu elitsha, njengelizwe elikhulu lemveliso elijikelezayo, i-PV yaseTshayina efakelweyo umthamo isoloko igcina ukuhambela phezulu.Ukususela ngo-2010, ukuveliswa kweeseli ze-photovoltaic e-China kudlule i-50% yemveliso epheleleyo yehlabathi, eyona nto ingqiqo.Ngaphezu kwesiqingatha semboniselo ye-photovoltaic yehlabathi iveliswa kwaye ithunyelwa ngaphandle.

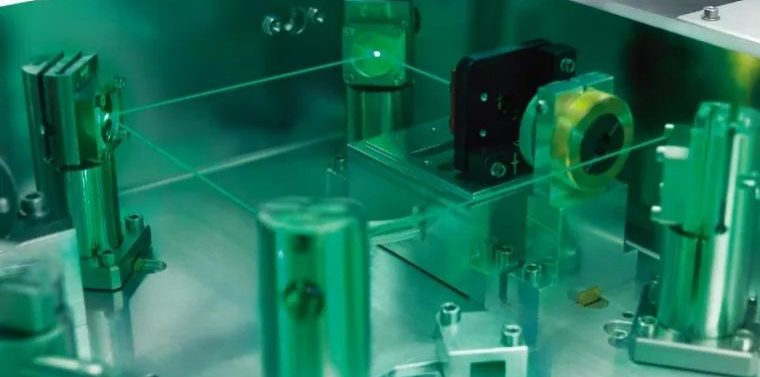

Njengesixhobo soshishino, i-laser iteknoloji ephambili kwishishini le-photovoltaic.I-Laser inokugxininisa umthamo omkhulu wamandla kwindawo encinci yecandelo lomnqamlezo kwaye uyikhulule, iphucule kakhulu ukusebenza kakuhle kokusetyenziswa kwamandla, ukuze ikwazi ukusika izinto ezinzima.Ukwenziwa kwebhetri kubaluleke kakhulu kwimveliso ye-photovoltaic.Iiseli ze-silicon zidlala indima ebalulekileyo ekuveliseni amandla e-photovoltaic, nokuba ngaba iiseli ze-silicon ze-crystalline okanye iiseli ze-silicon zefilimu.Kwiiseli ze-silicon zekristale, i-crystal-high-purity single / polycrystal isikwa kwii-silicon wafers zeebhetri, kwaye i-laser isetyenziselwa ukusika ngcono, ukumila, kunye nombhali, kwaye emva koko umtya iiseli.

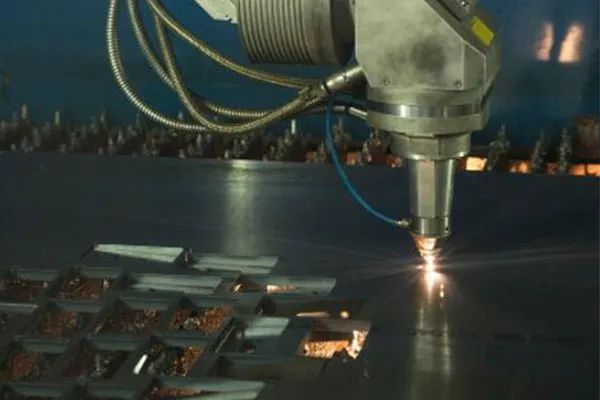

01 Umphetho webhetri unyango lokugqitha

Eyona nto iphambili yokuphucula ukusebenza kakuhle kweeseli zelanga kukunciphisa ilahleko yamandla ngokufakwa kombane, ngokuqhelekileyo ngokufaka kunye nokudlula imiphetho ye-silicon chips.Inkqubo yesiNtu isebenzisa iplasma ukunyanga ukugquma komphetho, kodwa iikhemikhali zokujongisisa ezisetyenziswayo zibiza imali eninzi kwaye ziyingozi kokusingqongileyo.I-Laser enamandla amakhulu kunye namandla aphezulu inokukhawuleza idlule umda weseli kwaye ithintele ukulahlekelwa kwamandla amaninzi.Nge-laser eyenziwe i-groove, ilahleko yamandla ebangelwa kukuvuza kwangoku kweseli yelanga kuncitshiswe kakhulu, ukusuka kwi-10-15% yelahleko ebangelwe yinkqubo yokubhala imichiza yemveli ukuya kwi-2-3% yelahleko ebangelwa yitekhnoloji yelaser. .

02 Lungiselela kwaye Ubhale

Ukulungelelanisa ii-silicon wafers ngelaser yinkqubo eqhelekileyo kwi-intanethi yochungechunge oluzenzekelayo lwe-welding yeeseli zelanga.Ukudibanisa iiseli zelanga ngale ndlela kunciphisa iindleko zokugcina kwaye kwenza ukuba iintambo zebhetri zemodyuli nganye zicwangciswe kwaye zidibanise.

03 Ukusika kunye nokubhala

Okwangoku, kuhambele phambili ngakumbi ukusebenzisa i-laser ukukrwela kunye nokusika ii-silicone wafers.Inokusebenzisa ukuchaneka okuphezulu, ukuchaneka kokuphindaphinda okuphezulu, ukusebenza okuzinzileyo, isantya esikhawulezayo, ukusebenza okulula kunye nokugcinwa okufanelekileyo.

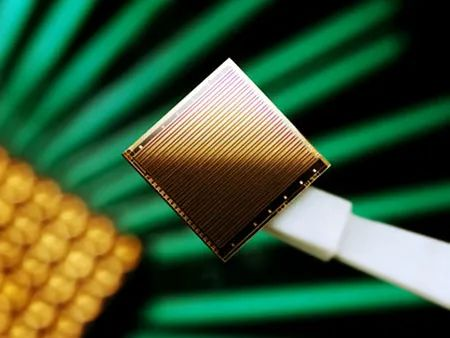

04 Uphawu lwewafer yesiliconnge

Ukusetyenziswa okuphawulekayo kwelaser kwi-silicon photovoltaic industry kukuphawula i-silicon ngaphandle kokuchaphazela ukuqhuba kwayo.Ukuleyibheliwa kweWafer kunceda abavelisi balandele ikhonkco labo lokubonelela ngelanga kunye nokuqinisekisa umgangatho ozinzile.

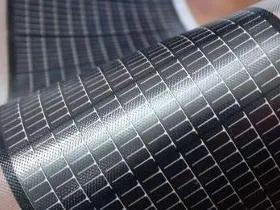

05 Ukukhutshwa kwefilimu

Iiseli zelanga ezinqabileyo zefilimu zixhomekeke ekubekweni komphunga kunye netekhnoloji yokubhala ukuze ukhethe ngokukhetha iileya ezithile ukuze ufezekise ukwahlulwa kombane.Uluhlu ngalunye lwefilimu kufuneka lufakwe ngokukhawuleza ngaphandle kokuchaphazela ezinye iileyile zeglasi ye-substrate kunye ne-silicon.Ukukhutshwa kwangoko kuya kukhokelela kumonakalo wesekethe kwiglasi kunye neengqimba ze-silicon, eziya kukhokelela kukusilela kwebhetri.

Ukuqinisekisa ukuzinza, umgangatho kunye nokufana kokusebenza kokuveliswa kwamandla phakathi kwamacandelo, amandla ombane we-laser kufuneka ahlengahlengiswe ngononophelo kwi-workshop yokuvelisa.Ukuba amandla e-laser akakwazi ukufikelela kwinqanaba elithile, inkqubo yokubhala ayinakugqitywa.Ngokufanayo, umqadi kufuneka ugcine amandla ngaphakathi kwinqanaba elincinci kwaye uqinisekise i-7 * 24 iyure yokusebenza imeko kumgca wendibano.Zonke ezi zinto zibeka phambili iimfuno ezingqongqo kakhulu zokucaciswa kwe-laser, kwaye izixhobo zokubeka esweni ezinzima kufuneka zisetyenziswe ukuqinisekisa ukusebenza okuphezulu.

Abavelisi basebenzisa umlinganiselo wamandla we-beam ukwenza ngokwezifiso i-laser kunye nokulungelelanisa ukuhlangabezana neemfuno zesicelo.Kwii-lasers zamandla aphezulu, kukho izixhobo ezininzi zokulinganisa amandla ahlukeneyo, kwaye ii-detectors zamandla aphezulu zinokuphula umda wee-lasers phantsi kweemeko ezikhethekileyo;IiLaser ezisetyenziselwa ukusika iglasi okanye ezinye izicelo zokubeka zifuna ingqalelo kwiimpawu ezintle zomthi, hayi amandla.

Xa ifilimu encinci ye-photovoltaic isetyenziselwa ukucima izinto zombane, iimpawu ze-beam zibaluleke ngakumbi kunamandla okuqala.Ubungakanani, imilo kunye namandla adlala indima ebalulekileyo ekuthinteleni ukuvuza kwangoku kwebhetri yemodyuli.I-laser beam ekhupha imathiriyeli ye-photovoltaic efakwe kwi-plate yeglasi esisiseko nayo ifuna ukulungiswa kakuhle.Njengendawo yoqhagamshelwano elungileyo yokuvelisa iisekethe zebhetri, umqadi kufuneka uhlangabezane nayo yonke imigangatho.Imiqadi ekumgangatho ophezulu kuphela enokuphinda-phinda okuphezulu inokucima ngokuchanekileyo isekethe ngaphandle kokonakalisa iglasi engezantsi.Kule meko, i-thermoelectric detector ekwazi ukulinganisa amandla e-laser beam ngokuphindaphindiweyo iyafuneka.

Ubungakanani beziko le-laser beam buya kuchaphazela indlela yokukhutshwa kwayo kunye nendawo.Ukujikeleza (okanye i-ovality) ye-beam iya kuchaphazela umgca wombhali oqikelelweyo kwimodyuli yelanga.Ukuba i-scribing ayilingani, i-ellipticity ye-beam engahambelani iya kubangela iziphene kwimodyuli yelanga.Ubume bomqadi wonke buchaphazela nokusebenza kwe-silicon doped structure.Kubaphandi, kubalulekile ukukhetha i-laser enomgangatho olungileyo, kungakhathaliseki ukuba isantya sokucubungula kunye neendleko.Nangona kunjalo, kwimveliso, iilaser ezitshixwayo zidla ngokusetyenziselwa iipulse ezimfutshane ezifunekayo ukuze zibe ngumphunga kwimveliso yebhetri.

Izixhobo ezitsha ezifana ne-perovskite zibonelela ngenkqubo yokwenziwa ngexabiso eliphantsi neyahluke ngokupheleleyo kwiibhetri ze-silicon zekristale.Enye yeenzuzo ezinkulu ze-perovskite kukuba inokunciphisa impembelelo yokucubungula kunye nokuveliswa kwe-silicon ye-crystalline kwindalo ngelixa igcina ukusebenza kakuhle.Okwangoku, ukufakwa komphunga kwezixhobo zayo kusebenzisa itekhnoloji yokucubungula i-laser.Ke ngoko, kwishishini le-photovoltaic, itekhnoloji ye-laser isetyenziswa ngakumbi kwinkqubo yedoping.I-photovoltaic lasers isetyenziswa kwiinkqubo ezahlukeneyo zokuvelisa.Kwimveliso yeeseli ze-crystal ze-silicon zelanga, itekhnoloji ye-laser isetyenziselwa ukusika iitshiphu ze-silicon kunye nokufakwa komphetho.I-doping yomda webhetri kukuthintela isiphaluka esifutshane se-electrode yangaphambili kunye ne-electrode yangasemva.Kwesi sicelo, itekhnoloji yelaser idlule ngokupheleleyo kwezinye iinkqubo zemveli.Kukholelwa ukuba kuya kubakho izicelo ezininzi ngakumbi kunye ne-laser technology kulo lonke ishishini elihlobene ne-photovoltaic kwixesha elizayo.

Ixesha lokuposa: Oct-14-2022