Imoto yokuqhuba isithuthi sombane ikakhulu yenziwe ngestator, rotor, casing, connector, rotary transformer kunye nezinye iindawo.Ke ngoko, umlambo onyukayo wemoto yemoto yombane yindibano kunye nendibano, apho indibano ikwinqanaba lesithathu lemoto yemoto yombane, indibano yinxalenye yenqanaba lesibini lemoto yemoto yombane, kunye nemoto yombane. Inqanaba lokuqala lenxalenye yemoto yesithuthi sombane.

Iphepha lensimbi ye-silicon: icandelo eliphambili lemoto

Iphepha lensimbi le-silicon licandelo eliphambili lesixhobo sombane kunye nombane.Ukusebenza kwayo akuhambelani ngokuthe ngqo kuphela nokulahlekelwa kwamandla ombane, kodwa kuhambelana nokusebenza, umthamo kunye nobunzima bemoto kunye ne-transformer.

Ukusebenza kwe-silicon sheet sheet ngokuqhelekileyo kufunwa ngolu hlobo lulandelayo:

1. Imilo yepleyiti elungileyo kunye nokugquma komhlaba;

2. Ukuchaneka okuphezulu kwe-dimensional kunye nomlinganiselo omncinci wobunzima bepleyiti efanayo;

3. Ineempawu ezilungileyo ze-electromagnetic kunye nesakhiwo sokujongwa kweenkozo ezihlangabezana neemfuno zokusetyenziswa.

Ukuguqulwa kweteknoloji yokusika i-laser ye-silicon sheet sheet

- Uqhubekeko lwemveli

Indlela yokucutshungulwa yesiko ye-silicon sheet yentsimbi ikakhulu ibetha ngesantya esiphezulu

1.Ukuvulwa komngundo kuyadingeka kwisigaba sokuqala

2.Ixabiso eliphezulu le-R & D

- Ukusika kweLaser

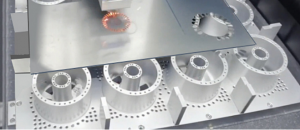

Ngoku, ukusika kwe-laser kusetyenziselwa ukwenza i-silicon iron sheet, eyisombulula ingxaki enzima yokusetyenzwa kwe-silicon yentsimbi.

1. Umjikelo omfutshane we-R & D, akukho kuvulwa ngundo

2.Nawuphi na umzobo unokunqunyulwa

3.I-Flexible kwaye ifanelekile

(Umatshini wokusika we-laser ochanekileyo we-alloyEPLC6045)

I-EPLC6045 ithatha iqonga lomatshini wegranite wendalo, ukuchaneka okuphezulu okuphezulu kwe-aluminium eshukumayo kunye nembonakalo yephepha lentsimbi yokupakisha, kunye nonyango lwepeyinti ekwazi ukumelana nobushushu ukubonelela ngokhuseleko olululo kunye nomthamo wokhuseleko wokutywina kwindawo yokuhlangabezana neemfuno zenkqubo.

Ukumisa ukuchaneka:±3um(X1);±5um(X2);±3um(Y); ±3um(Z);±15arcsec(θ));

Ukuphindaphinda ukuchaneka kwendawo:±1um(X1);±3um(X2);±1um(Y);±1um(Z);±3arcsec(θ));

Uluhlu lokulungisa indiza:I-450mm * 600mm, igubungela iimfuno zobungakanani beenjini ezininzi zamandla amatsha (ifomathi enkulu inokwenziwa ngokwezifiso).

Isixhobo sekhemikhali esilungiselelweyo:i-vacuum adsorption yamkelwa, kwaye indawo ye-adsorption ilungiselelwe ngokweprofayili yemveliso.Iimpompo ezahlukeneyo ze-vacuum zingakhethwa.

Ixesha lokuposa: Aug-18-2022