Yintoni ukungena kwe-welding?Ibhekiselele kubunzulu bokunyibilika kwesiseko sesinyithi okanye intsimbi yentsimbi engaphambili kwicandelo lomnqamlezo wejoyinti edityanisiweyo.

Amalungu adityanisiweyo aquka: i-weld seam (0A), indawo yokudibanisa (AB) kunye nendawo echaphazelekayo yokushisa (BC).

Inyathelo 1: Iisampulu

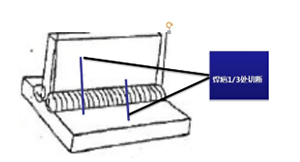

(1) Ukusika indawo ye-welding isampuli yokungena: a.Kuphephe ukuqala kunye nokumisa izikhundla

b.Sika kwi-1/3 yesiva se-weld

c.Xa ubude bebala le-weld lingaphantsi kwe-20mm, yinqumle embindini wesiva se-weld.

(2) Ukusika

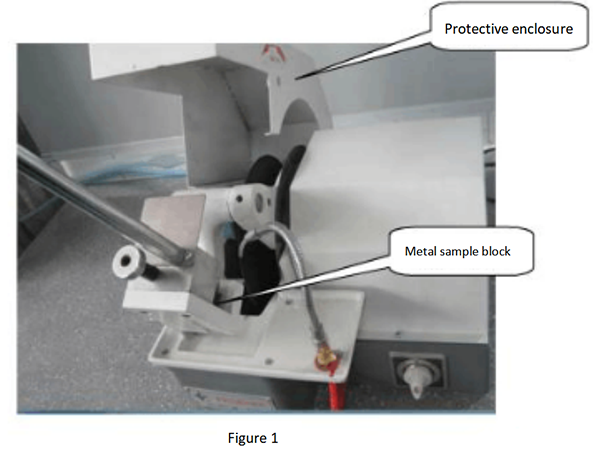

A. Qhagamshela umbane kwaye ujonge ukuba isixhobo sokulinganisa siyahlangabezana neemfuno zovavanyo;Njengoko kuboniswe kuMzobo 1, vula indlu yokukhusela yomatshini wokusika i-metallographic kwaye ufake ibhloko yesampula yensimbi ukuze ihlolwe.

(Qaphela: Qinisekisa ukulungisa ibhloko yentsimbi ngokupheleleyo!)

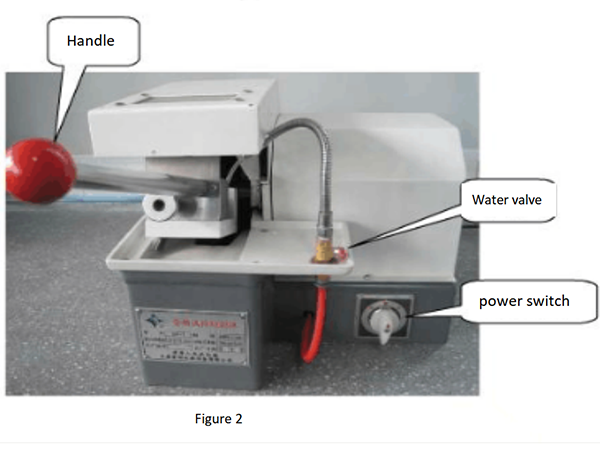

b.Njengoko kuboniswe kuMfanekiso 2, vala igobolondo ekhuselayo yomatshini wokusika i-metallographic, vula i-valve yamanzi, kwaye uvule umbane wombane;Bamba umqheba womatshini wokusika i-metallographic kwaye ucofe ngokucothayo ujonge ezantsi ukusika isampuli yesinyithi.Emva kokusika, ubude, ububanzi kunye nokuphakama kwesampula yensimbi kuya kuba ngaphantsi kwe-4mm;Vala ivalve yamanzi, cima amandla, kwaye ukhuphe isampuli yesinyithi.

b.Njengoko kuboniswe kuMfanekiso 2, vala igobolondo ekhuselayo yomatshini wokusika i-metallographic, vula i-valve yamanzi, kwaye uvule umbane wombane;Bamba umqheba womatshini wokusika i-metallographic kwaye ucofe ngokucothayo ujonge ezantsi ukusika isampuli yesinyithi.Emva kokusika, ubude, ububanzi kunye nokuphakama kwesampula yensimbi kuya kuba ngaphantsi kwe-4mm;Vala ivalve yamanzi, cima amandla, kwaye ukhuphe isampuli yesinyithi.

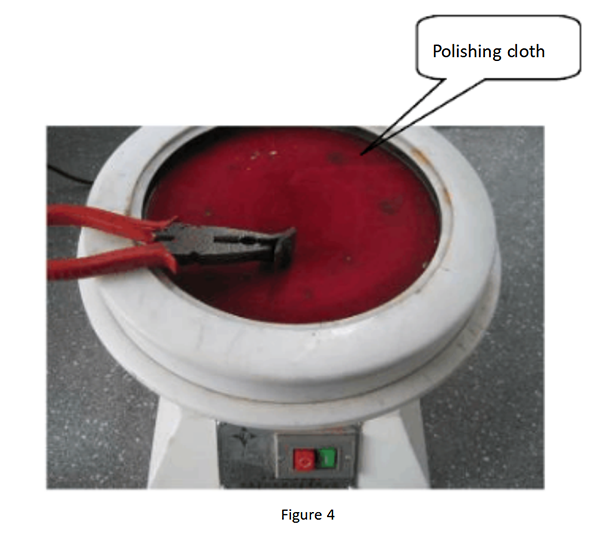

Inyathelo lesi-3: Ukonakala

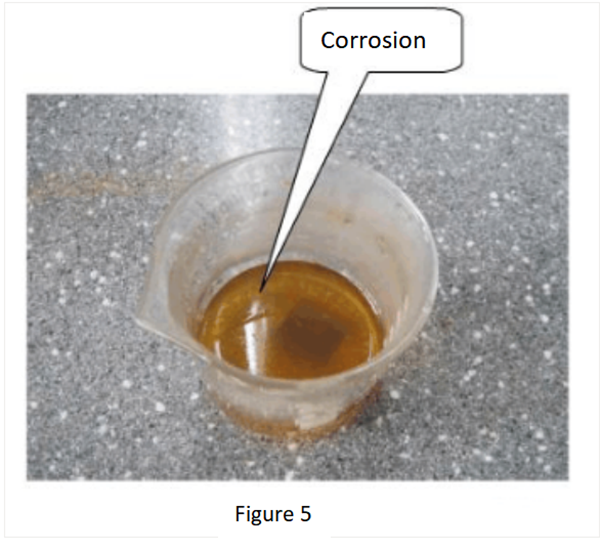

(1) Njengoko kubonisiwe kumfanekiso wesi-5, sebenzisa utywala obupheleleyo kunye ne-nitric acid ukulungiselela isisombululo sokubola (i-3-5% ye-nitric acid kunye notywala) kwikomityi yokulinganisa, faka isampuli yesinyithi kwisisombululo sokuhlwa okanye usebenzise ibrashi encinci ukuhlamba. umphezulu osikiweyo wokonakala.Ixesha le-corrosion li malunga ne-10-15 imizuzwana, kwaye umphumo othile wokutshatyalaliswa kufuneka uhlolwe ngokubonakalayo.

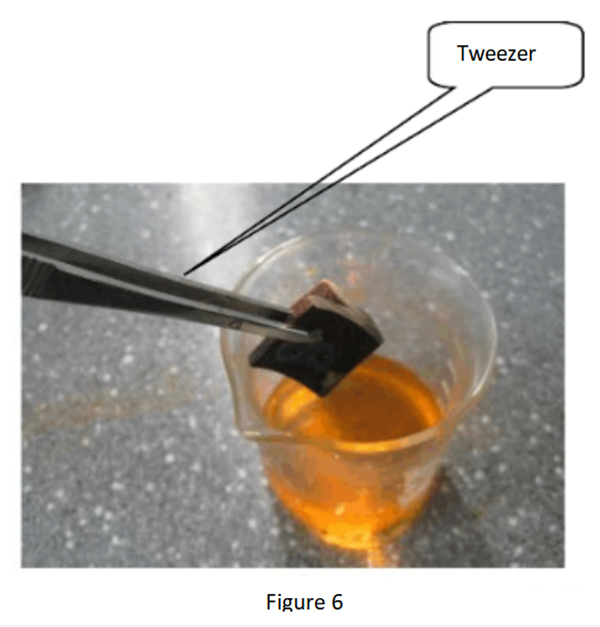

(2) Njengoko kubonisiwe kwi-Fig. 6, emva kokugqwala, khupha ibhloko yesampulu yesinyithi kunye ne-tweezers (qaphela: musa ukuchukumisa ulwelo lwe-corrosion ngezandla), kwaye uhlambulule isisombululo se-corrosion ebusweni bebhloko yesampula yesinyithi ngokucocekileyo. amanzi.

(1) Vuthela zome

Inyathelo 4: Ukuhlolwa kwendlela yokungena kwi-welding

| T (mm) bubunzima bepleyiti | |||

| Umlinganiselo omdala | Ibenchmark entsha | ||

| Ubukhulu bepleyiti | Idatha yokungena | Ubukhulu bepleyiti | Idatha yokungena |

| ≤3.2 | Ngaphezulu kwe-0.2 * t | t≤4.0 | Ngaphezulu kwe-0.2 * t |

| 4.0<t≤4.5 | Ngaphezulu kwe-0.8 | ||

| 3.2~4.5(Kuquka 4.5) | Ngaphezulu kwe-0.7 | 4.5<t≤8.0 | Ngaphezulu kwe-1.0 |

| t=9.0 | Ngaphezulu kwe-1.4 | ||

| 4.5 | Ngaphezulu kwe-1.0 | t≥12.0 | Ngaphezulu kwe-1.5 |

| Qaphela: Ukuwelda kwepleyiti ebhityileyo kunye nepleyiti eshinyeneyo kusekwe kwipleyiti encinci | |||

(1.2) Idatum yokungena iWelding (enobude bomlenze obubonisa ukungena)

| L (mm) bubude bonyawo | |

| Ubude bonyawo | Idatha yokungena |

| L≤8 | Ngaphezulu kwe-0.2 * L |

| L>8 | ngaphezulu kwe-1.5mm |

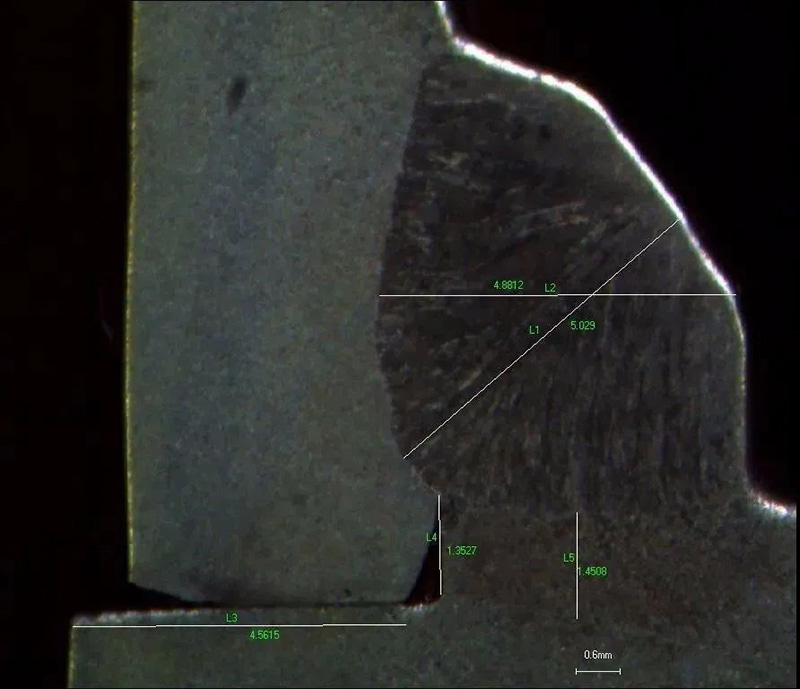

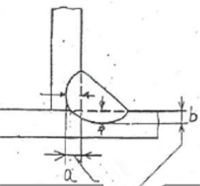

(2) Umlinganiselo we-welding yokungena (umgama a kunye no-b kukungena kwe-welding)

(3) Izixhobo zokuhlola ukungena kwe-welding

Inyathelo lesi-5: Ingxelo yokuhlolwa kokungena kwe-welding kunye nokugcinwa kweesampuli

(1) Ingxelo yokuhlola ukungena kwe-welding:

a.Ukongezwa kwedayagram enqamlezileyo yecandelo elihloliwe

b.Phawula indawo yokulinganisa yokungena kwe-welding kumzobo

c.Ukongezwa kwedatha

(2) Imigaqo yokugcinwa kweesampulu zokungena kwi-welding:

a.Ukugcinwa kwesakhelo S iinxalenye ze-13 iminyaka

b.Amalungu ngokubanzi aya kugcinwa iminyaka emi-3

c.Ukuba kuchazwe ngenye indlela kumzobo, kuya kuphunyezwa ngokweemfuno zomzobo

(Umphezulu wokuhlolwa kokugqobhoza unokuncamathelwa ngokuncamathelisa okucacileyo ukulibazisa ukurusa)

Ixesha lokuposa: Dec-22-2022