Inkqubo yokulungisa iLaser Brazing

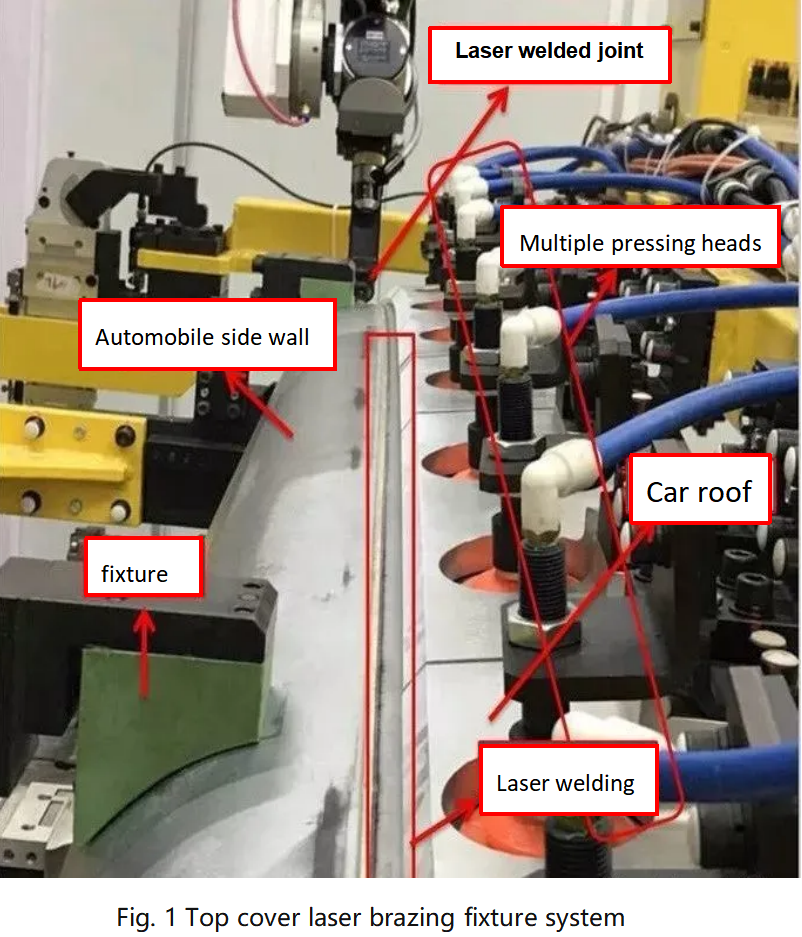

Ngexesha le-laser welding, kuyimfuneko ukuba ubambe ipleyiti yentsimbi edityanisiweyo ngokuqinileyo ngokwaneleyo, ngoko ke iiclamps ezikhethekileyo ziya kuyilwa.I-laser welding fixture inomthamo omkhulu kunye nesakhiwo esinzima.Sisakhiwo sesakhelo ngokubanzi.Amacala asekhohlo nasekunene omzimba wesithuthi axhaswa ziibhloko zokulungisa kwaye anyanzeliswe ngamasilinda emva kokumiswa kunye nenkxaso.Inxalenye ephezulu yenzelwe indawo ekhethekileyo kunye ne-gripper yokucinezela i-laser brazing yophahla lwemoto, ecinezelwe ngeentloko ezininzi.Irobhothi ibamba uphahla, ilubeke emzimbeni, kwaye iyibambe ngecylinder, ukuze imiphetho yentsimbi yomzimba idityaniswe ilingane ngokwaneleyo.Njengoko kubonisiwe kuMfanekiso 1.

Imiba yenkqubo

• · Ubushushu

• · I-engile yokwenzeka kwe-laser beam

• · Ukudibanisa kunye nokungagxininisi

• · Ubunzulu bokungena kwe-welding

• · Impembelelo yesantya se-welding kumandla we-laser welding

Uvavanyo

• 、Ukuhlolwa okubonwayo

• · Ngokomgangatho waseJamani wePV 6917 (inokufumaneka ngokuqhagamshelana nombhali);

• Uhlolo olubonwayo luya kwenziwa kwindibano nganye engasebenziyo;

• Gxininisa ekubhaqweni kokungena kweweld (njengokungena okungaphelelanga, ukugqobhoza nokutshisa), kwaye uthathele ingqalelo ubume bomphezulu weweld (efana nokutshiza kunye ne-porosity);

Indlela yokuvavanya i-laser brazing yokuhlolwa okubonakalayo iboniswe kwiThebhile 1.

| Itheyibhile yoku-1 yoVavanyo loMgangatho weLaser Brazing | ||

| Inombolo yothotho | Inkcazo yesiphene | Uvandlakanyo lwesiphene |

| 1 | Iipore eziveziweyo | Ukuba iimeko zivumela, umphezulu unokulungiswa ngokude nje awuchaphazeli umsebenzi;Imingxuma yomoya enobukhulu obungaphezu kwe-0.2mm kufuneka ilungiswe |

| 2 | Ukuphuphuma kweSolder (kakhulu kakhulu) | Ukuba iimeko zivumela, umphezulu unokulungiswa ngokude nje awuchaphazeli umsebenzi;Inokulungiswa |

| 3 | I-Layer ripple kumphezulu we-weld | I-joint kufuneka izaliswe nge-solder ngokuqhubekayo;Inokulungiswa |

| 4 | Ukuqhekeka komphezulu (okunqamlezayo kunye ne-longitudinal) kwenzeka kwi-weld | Ukuba iimeko zivumela, umphezulu unokulungiswa ngokude nje awuchaphazeli umsebenzi;Inokulungiswa |

| 5 | Ukuqhekeka komphezulu (i-transverse kunye ne-longitudinal) kwenzeka kwisiseko sesinyithi | Ayinakufaneleka, ifuna ukulungiswa |

| 6 | Ukungena kwesiseko sesinyithi | Ayinakufaneleka, ifuna ukulungiswa |

| 7 | Ukungena ngaphantsi kunye nokungaphelelanga | Ayinakufaneleka, ifuna ukulungiswa |

| 8 | isitshizi | Ukuba iimeko zivumela, umphezulu unokulungiswa ngokude nje awuchaphazeli umsebenzi;Inokulungiswa |

| 9 | Ayinanyama | Akuvumelekanga, ukulungiswa kuyafuneka |

| 10 | Isiphelo sokuqala asifakwanga, kwaye i-terminal ifakwe | Akuvumelekanga, ukulungiswa kuyafuneka |

| 11 | I-Weld ayikho (isithuba esikhulu esihambelanayo) | Akuvumelekanga, ukulungiswa kuyafuneka |

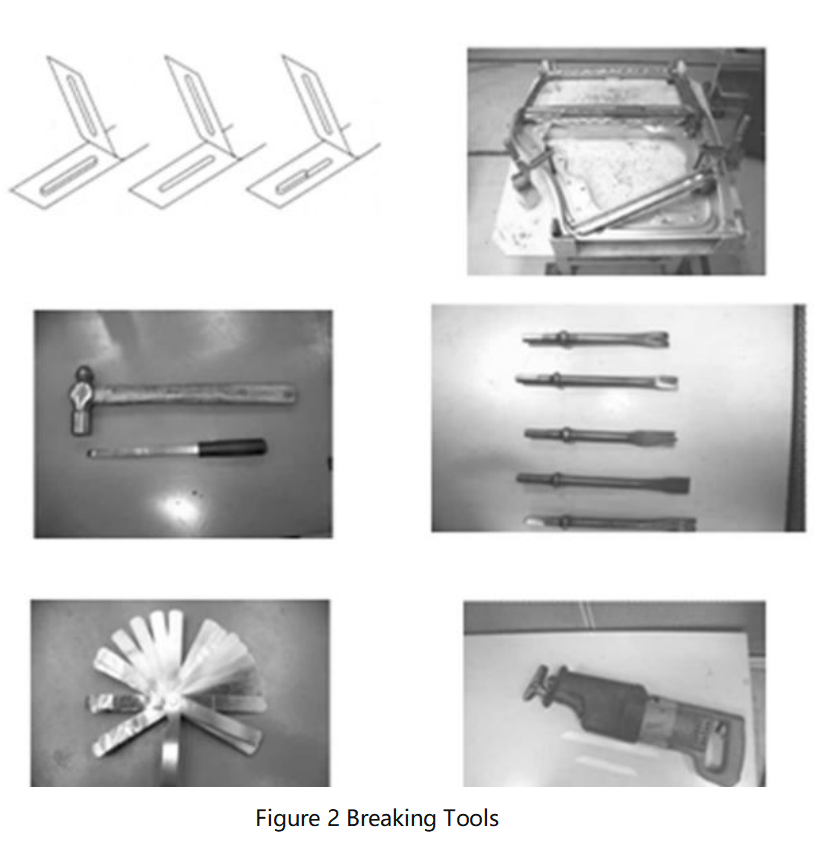

2 、 Ukuhlolwa okutshabalalisayo

Izixhobo zokuhlola ezonakalisayo ziboniswe kuMfanekiso 2:

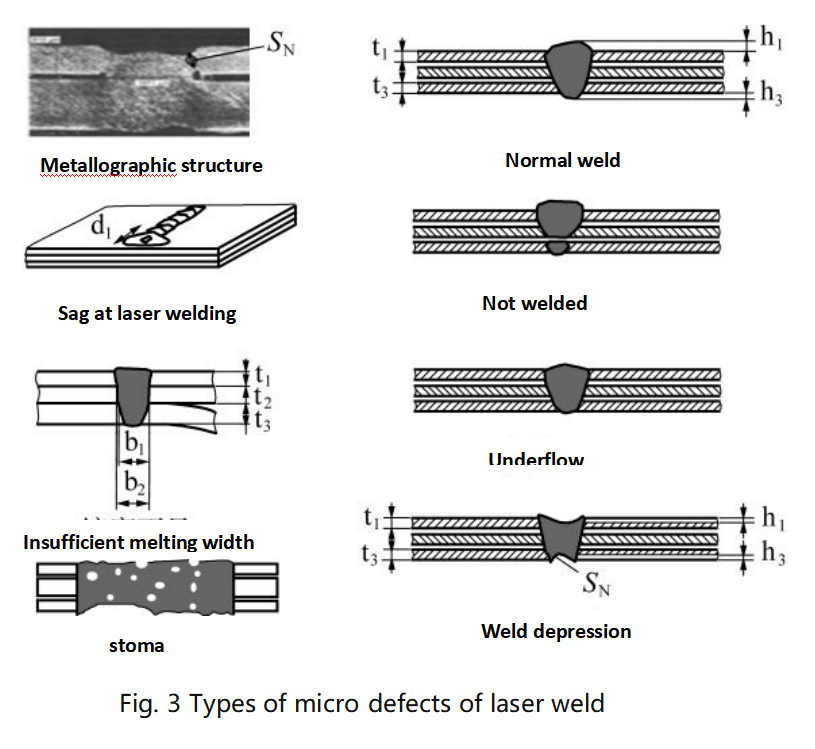

3 、 Uhlalutyo lweMetallographic Microscopic

Iindidi zeziphene ezincinci ze-laser weld ziboniswe kuMfanekiso 3:

4,NDT

I-Ultrasonic, i-X-ray kunye nezinye izixhobo zingasetyenziselwa ukuhlola umgangatho we-laser welding.

Isishwankathelo

Ngokweempembelelo zokwenyani zesicelo setekhnoloji ye-laser welding kwizityalo zemoto, kunokubonwa ukuba ukuwelda kwelaser akunakunciphisa kuphela ubunzima bomzimba wesithuthi, ukuphucula ukuchaneka kwendibano yomzimba wesithuthi, kodwa kukwanyusa kakhulu amandla esithuthi. umzimba, ukunika abasebenzisi ukhuseleko olungcono ngelixa besonwabela intuthuzelo.Kukholelwa ukuba ngokuphumelela okuqhubekayo kweengxaki zetekhnoloji ye-laser welding kunye nokuphuculwa okuqhubekayo kwenkqubo yokuvelisa, i-laser welding iya kuba yinxalenye ebalulekileyo yomzimba wemoto wexesha elizayo kwinkqubo yokwenziwa emhlophe.

Ixesha lokuposa: Jan-09-2023