Imbali yophuhliso lwe-laser welding ephathwayo ——-isizukulwana sesithathu somatshini wokuwelda welaser (2)

Okwangoku, kukho iindlela ezimbini eziphambili zokujingisa intloko ye-welding "yesizukulwana sesithathu somatshini we-laser welding": enye luhlobo lwe-galvanometer, kwaye enye luhlobo lwe-rotary.

Uhlobo lweGalvanometer

Uhlobo olujikelezayo

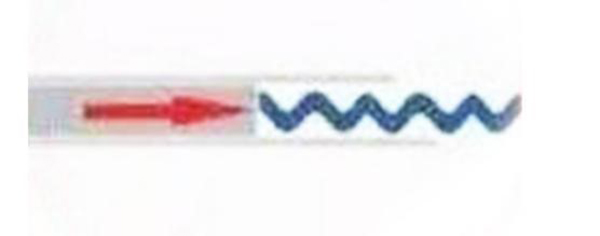

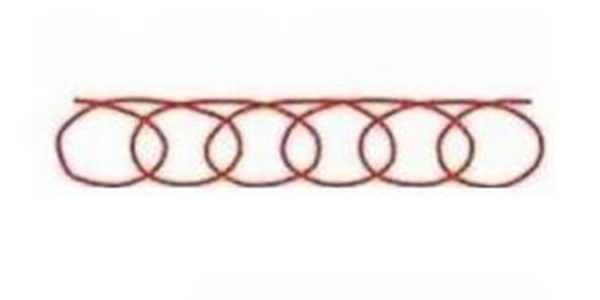

Ukuba i-frequency ye-swing iyancitshiswa kwaye umgca othe ngqo udityaniswe ngesandla, iindlela ezimbini ze-welding ziya kubonisa ezi ngoma zimbini ezahlukeneyo, njengoko kubonisiwe kulo mfanekiso ulandelayo:

Uhlobo lweGalvanometer

Uhlobo olujikelezayo

Umzekelo, ukuba ukuwelda ngesandla kuthelekiswa nokuthunga iimpahla ngesandla, uhlobo lwegalvanometer kunye nohlobo olujikelezayo lufana neentlobo ezimbini zokuthunga, ezinokuthunga iimpahla kakuhle.Kuphela ngumbandela wembono ekulula ukuyisebenzisa.

| Imowudi yokujingi yeGalvanometer | Imowudi yokujingi ejikelezayo | |

| umthamo | Inkulu kancinci | Kancinci kancinci |

| ubunzima | Inzima kancinci | Ikhaphukhaphu kancinci |

| Uhlengahlengiso lomlilo | Iyakwazi ukulungiswa ngokuthe ngqo kwipaneli yokulawula | Kufuneka ukubuyisela i-hardware ukulungisa ubungakanani |

Oku kulandelayo yimeko yokusetyenziswa kwebala le-Chuangheng Laser "umatshini wokuwelda we-laser wesizukulwana sesithathu":

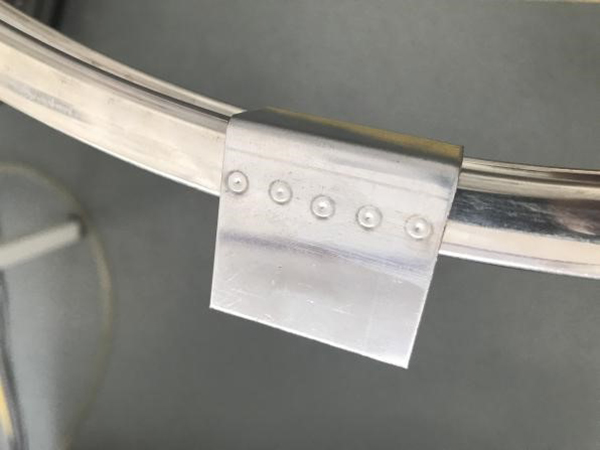

Ukuwelda kwesakhiwo sesihlalo semoto

Amandla okungena kwindawo yokuwelda angcono kunalawo e-argon arc welding

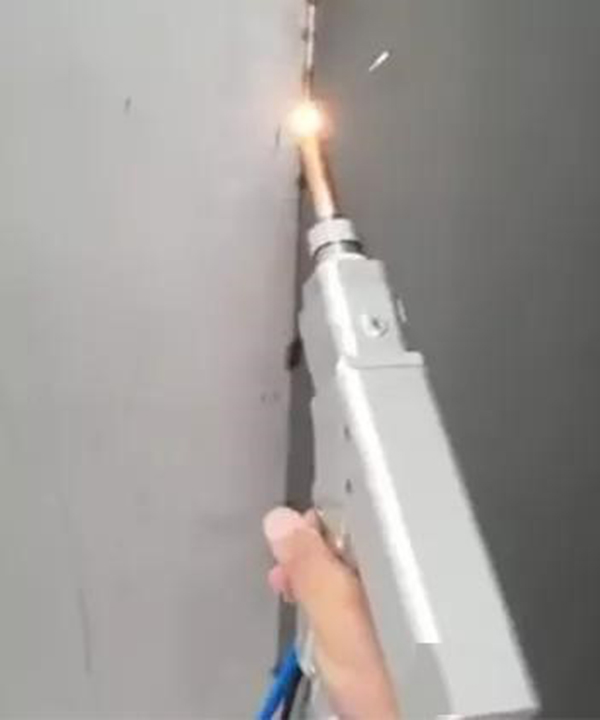

Ukukhupha i-welding ye-funnel

Ikhitshi kunye negumbi lokuhlambela

Ngaba ucinga ukuba akukho lula ukubona abantu abadumileyo kwi-intanethi apha, kwaye wenze ezakho iinzame.Kwi-2020, i-Chuangheng Laser iya kuqhubeka nokwenza imizamo yokuvavanya isizukulwana sesine seemveliso (i-wire feed handheld welding).

Nangona kunjalo, umbhali uhlala enenkxalabo yakhe malunga nale mveliso.Ukuwelda ngesandla kwelaser kuluhlu lwesine lweemveliso zelaser.Nangona izixhobo zinomsebenzi wokukhusela umhlaba, i-welding ebanjwe ngesandla emva kwayo yonke into.Ngexesha le-welding, kuya kubakho i-angle ethile phakathi kwentloko ye-welding kunye ne-workpiece surface, ukuze inxalenye ye-laser ibonakaliswe yizinto eziphathekayo, ngakumbi kwi-welding aluminium kunye nobhedu, ezizizixhobo ezibonisa kakhulu.Ke ngoko, abaqhubi kufuneka babenendawo yokusebenza eyahlukileyo kwaye banxibe izibuko ze-laser.

Imaski ekhuselayo enxitywa ngabasebenzi bangaphandle

Okokugqibela, hlalutya ulwalathiso lophuhliso lwe-laser welding ephathwayo.Ukuba ufuna ukufezekisa uluhlu olubanzi lokucubungula, kufuneka unciphise umthamo wezixhobo.Okwangoku, umthamo wentloko ye-welding isenkulu kakhulu.Ezinye iindawo ezincinci azilulanga ukusebenza, kwaye umsebenzi wokukhwela awulungelanga.

Okwangoku, ixabiso lemarike ye-1000 W i-welding ye-swing ebanjwe ngesandla ijikeleze i-80000, kusenzima kubathengi ngokubanzi ukuba bamkele.Ngokubhekiselele kukhuseleko, ikwayeyona nto ibalulekileyo ekufuneka iqwalaselwe ngoku.Ukuba amandla e-welding afunekayo adlula i-1500 W, kuyacetyiswa ukuba ukhethe izixhobo ze-laser welding ezizenzekelayo kunye nesigqubuthelo sokukhusela.

Ixesha lokuposa: Feb-13-2023