Njengoko sonke sisazi, abaqhubi, abavelisi bezixhobo, abavelisi bezixhobo kunye nabavelisi bezinto eziphathekayo baye bakhela ikhonkco leshishini lonxibelelwano olubunjiweyo lwephiramidi kunye.Kwishishini, itekhnoloji yokupakisha yesixhobo sonxibelelwano esiqhelekileyo sisebenzisa iglue ye-UV ukubopha kunye nokulungisa isixhobo kwindawo yokuhlangana.Okokuqala, i-glue ye-UV isetyenziswe kwi-junction yesixhobo, kwaye isibane se-UV sisetyenziselwa ukucima kunye nokuqinisa isixhobo.Le mowudi yoqhagamshelo lwesixhobo ineziphene ezininzi, ezinje ngobunzulu bokuphilisa;I-laser welding, uhlobo olutsha lweteknoloji yokuwelda, ineenzuzo ze-welding eqinile, i-deformation encinci, ukuchaneka okuphezulu, isantya esikhawulezayo kunye nolawulo olulula oluzenzekelayo, nto leyo eyenza ibe yenye yeendlela ezibalulekileyo zokupakisha iteknoloji yonxibelelwano lwe-optical device.Oku kulandelayo kuchaza itekhnoloji yomatshini we-laser welding kushishino lonxibelelwano lwamehlo.

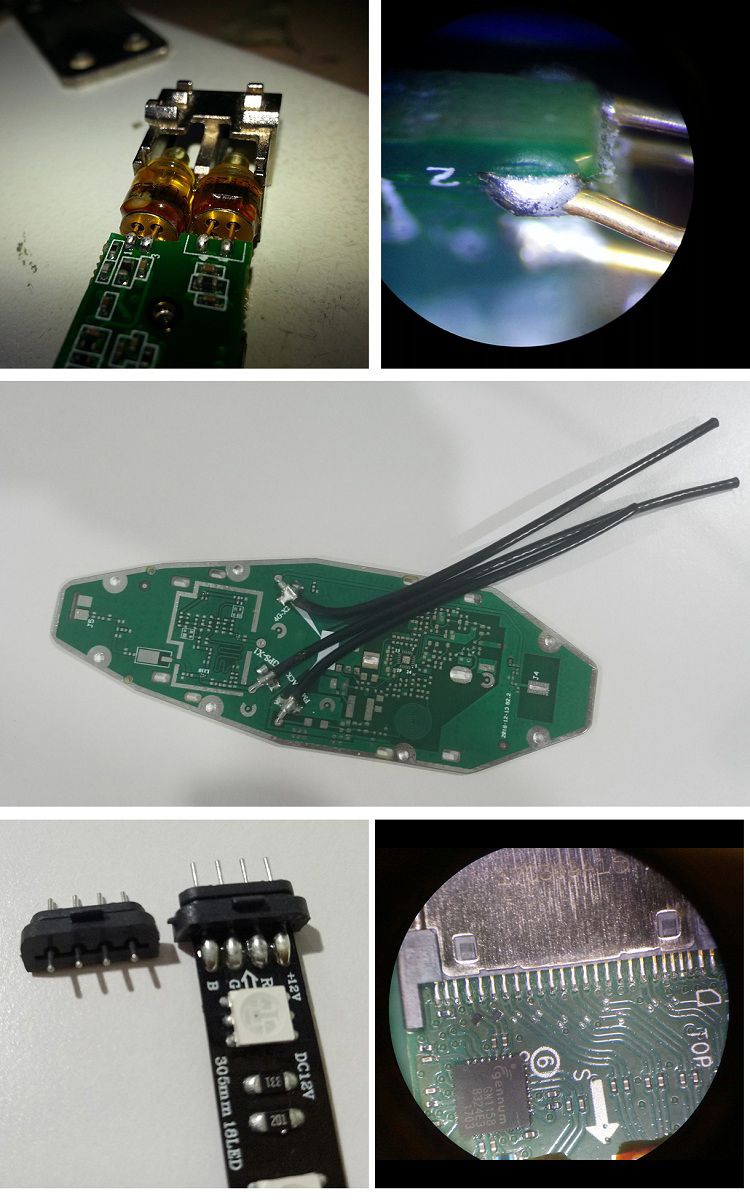

Izixhobo ze-Optical kunye neemodyuli ze-optical zibekwe phezulu kwezixhobo zonxibelelwano ze-optical.Umsebenzi ophambili wemodyuli ye-optical kukuqonda ukuguqulwa kwe-photoelectric.Ekubeni i-chip yimveliso ene-coefficient yobunzima obukhulu kwikhonkco loshishino lwemodyuli, emva kokuba i-chip engenanto kunye nebhodi ye-wiring ifezekise unxibelelwano oluncinci, kufuneka itywinwe kwiplastiki, iglasi, isinyithi okanye iqokobhe le-ceramic ngokusebenzisa iteknoloji yokupakisha ukuqinisekisa ukuba i-semiconductor edibeneyo ye-circuit chip isebenza ngokuqhelekileyo phantsi kweemeko ezahlukeneyo ezimbi.I-laser welding isetyenziswa kakhulu kule nkqubo.

Njengomgangatho ophezulu, ukuchaneka okuphezulu, ukusebenza kakuhle kunye nesantya esiphezulu sendlela yokuwelda, i-laser welding iye yaxhalabisa kwaye yasetyenziswa.Ngenxa yoxinaniso lwamandla aphezulu e-laser, ukuwelda kwelaser kuyakhawuleza, kunzulu kwaye kuncinci kwindawo echaphazelekileyo kubushushu, enokuqonda ukuwelda okuchanekileyo ngokuzenzekelayo.

Ngeemfuno ze-miniaturization, ukusebenza okuphezulu, imisebenzi emininzi kunye nexabiso eliphantsi lezixhobo zombane, itekhnoloji ye-laser welding, enezibonelelo ze-welding eqinile, i-deformation encinci, ukuchaneka okuphezulu, isantya esikhawulezayo kunye nokulula ukuyiqonda ulawulo oluzenzekelayo. enye yeendlela ezibalulekileyo zeteknoloji yokupakisha yesixhobo sonxibelelwano.Ukusetyenziswa kwayo kwinkqubo yokuvelisa izixhobo zonxibelelwano ze-optoelectronic, amacandelo kunye neemodyuli zinokuphucula ngokufanelekileyo ukuchaneka kwe-welding kunye nomgangatho we-welding.

Ixesha lokuposa: Dec-05-2022